3LPE/PP/FBE Coating

3LPE/PP/FBE EXTERNAL COATING

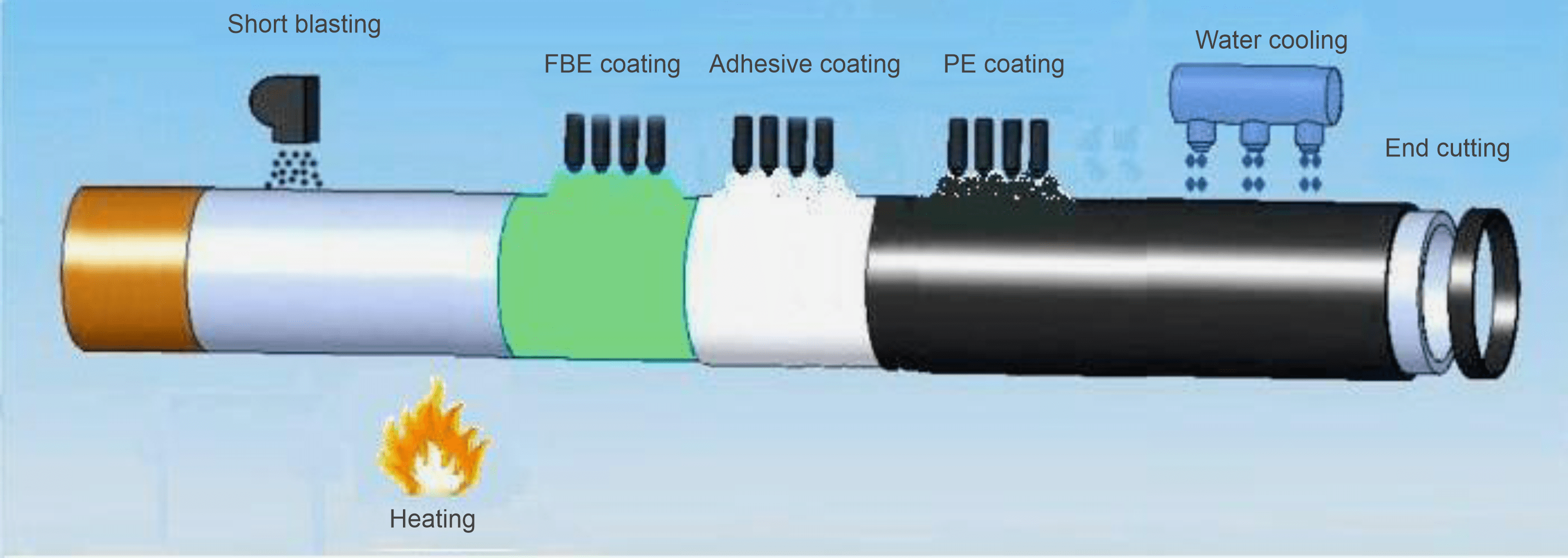

Three Layer Polyethylene/ Polypropylene coating Systems (3LPE/PP), a multi layer coating composed of three functional components: a high performance fusion bonded epoxy (FBE) followed by a copolymer adhesive and an outer layer of polyethylene/polypropylene which provides tough and durable protection. 3LPE/PP Systems provide excellent pipeline protection for small and large diameter pipelines with moderately high operating temperatures. |  | ||||

The 3-LPE/PP Coated Pipe are as Follows: Pipes are preheated, external blasting is carried out for cleaning and roughness then inspected. In case of high salt contamination the pipes are treated with phosphoric acid and washed with high pressure DM water to neutralize the chloride contents. The pipes are loaded on coating conveyor and heated between 180-2300C or as per powder manufacturer’s recommendation. | |||||

Three Layer PE/PP Coting Layer 1: This is the corrosion protective layer. This layer is of fusion bonded epoxy which offers very good corrosion protection. The fusion bonded epoxy has a very good bonding with the blasted steel surface. |  | ||||

Manufacture Process

| |||||

After coating, pipes are passed through quenching zone to bring down the temperature below 80°C for smooth handling and cut back operation as per client requirement. Pipes are tested with Holiday detector with 25 KV voltage to detect pin holes and other various testing peel test, thickness check, impact test and lab tests etc for coated pipes and raw materials. | |||||

Corrosion Resistance : · 3LPE/PP Coating prevents steel pipe from corrosion. · Excellent chemical resistance properties and resistance to cathodic disbandment. · 3LPE/PP Coating has got good resistance to moisture permeability. Mechanical Protection: · Top coat of polyethylene/polypropylene prevents abrasion and damage to fusion bonded epoxy during handling. · High Bond Strength : · The external coating and epoxy is bonded firmly to the steel pipe surface and this is mean to adhesion strength (ASTM D 4541). Applications 3LPE/PP coated steel pipes are mainly used in the following applications where the pipes are either buried or submerged: · Drinking water pipe lines, Oil and gas pipelines · In plant process water applications

| |||||

Standards and Specifications 3LPE/PP pipes are coated according to the following standards: · DIN 30670 · CSA Z245.21 · ISO 21809-1 · Or any other International standard/client specs | |||||

Capacity/Range Capacity per Hour: 800 (M2)FBE/3LPE/3LPP Minimum Pipe Diameter: 89.9mm(3’’) Maximum Pipe Diameter: 1500 MM (60″) Minimum Pipe Length: 6M Maximum Pipe Length15 M

| |||||

EXTERNAL COATING STANDARDS SURFACE PREPARATION : ISO 8501 – 1, ISO 8501 – 2, ISO 8501 – 3 POLYETHYLENE COATING : DIN 30670,EN 10288,UNI 9099,NFA 49710, AWWA C215 POLYPROPYLENE COATING : DIN 30678, NFA 49711 EPOXY COATING : EN 10289, AWWA C210, NFA 49709 BITUMEN : DIN 30673 FUSION BONDED EPOXY : AWWA C213 POLYURETHANE : EN 10290, AWWA C 222

INTERNAL COATING STANDARDS (LINING) SURFACE PREPARATION : ISO 8501 – 1, ISO 8501 – 2, ISO 8501 – 3 EPOXY LINING : EN 10289, AWWA C210, NFA 49709, API RP 5L2 FUSION BONDED EPOXY : AWWA C213, API 5L7

| |||||